There is a long and growing catalog of Interface solutions used in vehicle and urban mobility applications, from single load cells to entire force measurement systems.

Brake Pedal Testing

The first is the application of our BPL-300-C Pedal Load Cell, which was used to help a customer measure and refine brake pedal force during automobile testing. Automotive OEMs need to test brake pedals to ensure when a driver provides force on the brakes, the brake pads provide the correct corresponding force to slow down or stop an automobile at the desired speed. Interface’s BPL-300-C was installed on a brake pedal and then connected to a BTS-AM-1 Bluetooth Low Energy Strain Bridge Transmitter Module, which collects and transmits data to our BTS Toolkit Mobile App. This solution allowed the customer to record and review data from a mobile device while out on a test track. The force data helped the customer refine and confirm the design of its brake pedal system.

Drone Delivery

The next application example can be categorized under the realm of urban mobility. Recently, Interface has received requests for force solutions related to drones and more specifically, drone package delivery. Drone delivery provides shipping and fulfillment companies with the capability to vastly improve delivery times for customers. This novel solution is being deployed within several large companies such as Amazon, which received a lot of media attention about its plans to implement more drone technology into its shipping processes. One of the key steps in this process is designing the drone to measure the weight of the package it’s carrying so the propeller motors can compensate for weight shifting or uneven weight. In this application, Interface supplied four WMC Sealed Stainless Miniature Load Cells to measure the weight of the payload and detect in-motion weight shifting and uneven weight distribution. As the load cells detect this data, it will send a signal to the propeller to increase RPMs on the propellers and adjust balance and weight distribution.

Electric Vehicle

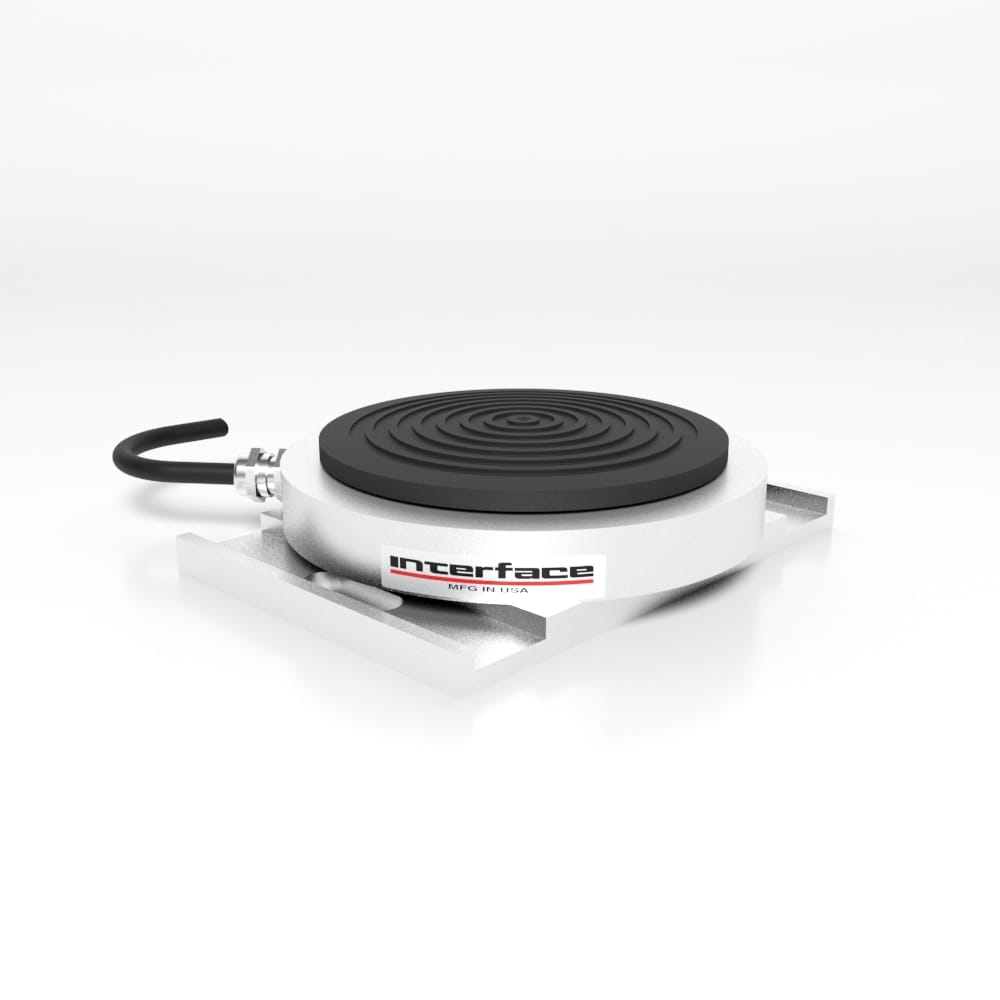

In the electric vehicle (EV) market, one of the most integral pieces of technology is the battery used to run every piece of hardware and software in the car. One of the critical tests performed on EV batteries is compression testing. As an EV battery is charged and stores more electrons, it swells. If the packaging housing the batteries is not intelligently designed to compensate for this swelling, you could have a major problem. For this challenge, Interface can supply a WMC miniature load cell. The load cell will measure compression force as a battery goes through charge cycles on a test stand to determine the force given off as the battery swells. This allows our customers to design the proper packaging for the batteries.

Engine Performance

The final application example is related to using force to measure engine performance. Force and torque sensors are often used in conjunction with a dynamometer, which isolates the engine’s power output to help quantify its overall performance. The solution Interface helped develop included a precision SSMF Fatigue Rated S-Type Load Cell attached to a torque arm which “feels” the torque from an engine loading system. The fatigue rating on the load cell allows it to accurately measure performance for extended cycles. A signal conditioner is also attached from the load cell to a computer to ensure clear transmission of data. This solution allows the engine manufacturer to accurately measure torque being produced by the engine. This data helps engineers analyze power transfer and ultimately tune the engine performance to where it needs it to be.